-

Solutions

Care Area Solutions

Standardize GCX mounting solutions throughout your healthcare facility.

IT and EMR Solutions

Mounting solutions for Information Technology and Electronic Medical Records equipment.

Mounting solutions based on your mounting location.

Medical Device Solutions

Mounting solutions designed specifically for your medical and patient monitoring devices.

-

Products

Arms

Variable Height

Carts and Roll Stands

Variable Height

Fixed Height

Accessories

- 10 x 25 mm Rails

- Barcode Scanner Mounts

- Baskets and Bins

- Cable Management

- Camera Mounts

- Channels

- CPU Mounts

- Data Capture Device Mounts

- Down Posts

- Drawers

- Gas Cylinder Mounts

- Gel Bottle Mount

- Handles

- Keyboard Trays and Plates

- Medical-Grade Power Strips

- Mountable Tablet Enclosures

- PolyQuip® Post and I.V. Bag Hanger Mounts

- Power Supply Mounts

- Probe Cup Mount

- Speaker Mount

- Tablet Integration

- Trays

- UPS Mounts

- USB Charging Modules

- VESA Adapter Plates

-

OEM Services

Mounting solutions for medical device OEM partners range from off-the-shelf to complete custom products.

Approach

Modalities

- Ventilation

- Ultrasound

- Patient Monitoring

- Telemedicine

- Surgical Navigation

- ECG Solutions

- Other Modalities

Our Expertise

-

Support

-

About GCX

Lilitab™ is now a part of GCX! Learn More

Manufacturing and Logistics

Our global manufacturing footprint provides responsive, cost-effective, and high-quality production and distribution

Manufacturing

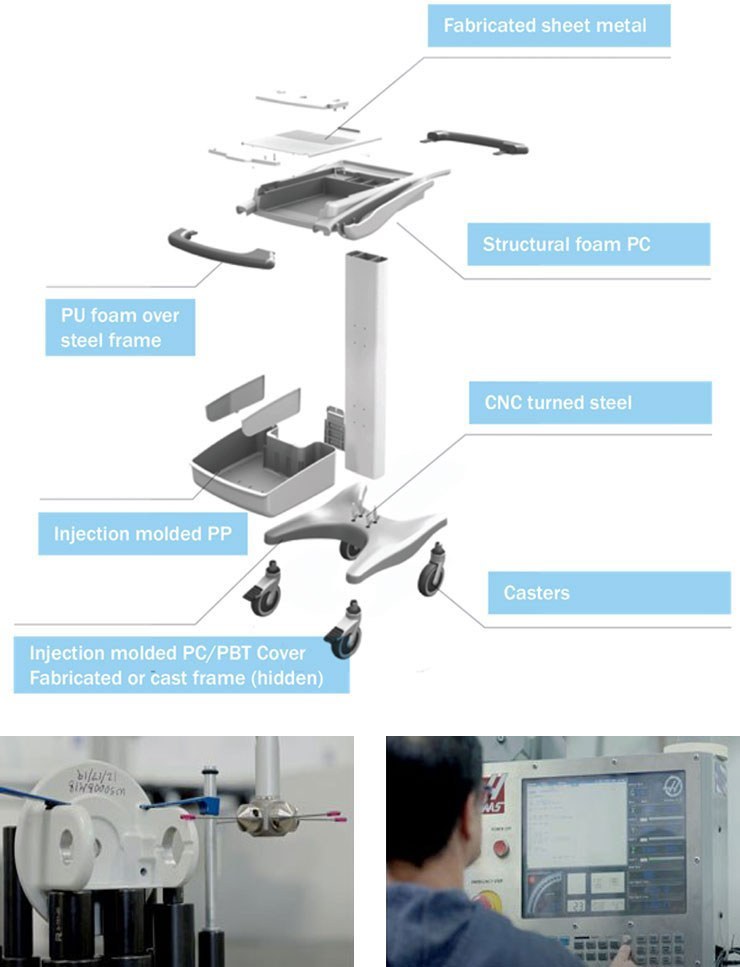

We begin every OEM project by identifying your needs, working from “the customer back,” and taking a total cost of ownership approach. This includes developing and proposing the most optimal supply chain model to establish a lead time, minimum order quantity to maximize responsiveness and control costs. Our engineering and manufacturing teams are available to quickly take a new program from early concept to mass production.

Our Quality Management System is ISO 13485 certified. The manufacturing processes that we leverage include:

- CNC milling and turning

- Sheet metal fabrication

- Aluminum extrusions

- Injection molding

- Die-cast aluminum and zinc

- Wire form

- Structural foam

- Sand casting

- Gravity-cast aluminum

- Vacuum forming

- Assembly

- Machining

- Finishing

Logistics

Our global footprint enables us to develop a logistics model that makes sense for you and enables us to:

- Provide local support and service

- Improve responsiveness by placing inventory where it is most valuable, near your end customer

- Reduce shipping costs by using regular containers transporting between GCX locations in the USA, Europe, and Asia

- Minimize your inventory through just-in-time replenishment and/or drop ship programs

GCX Operation Locations

Warehousing Assembly Packaging Sales Manufacturing Engineering Component Manufacturing & Sourcing Petaluma California, USA El Paso Texas, USA Tilburg The Netherlands Taipei Taiwan Shenzhen China Start a Project

Let’s work together to bring your next medical device or healthcare equipment to market quickly with our medical manufacturing experts and a custom-configured or brand new mounting solution.

"*" indicates required fields